rachke piping and mechanical

What We Do

Industrial Rigging

Rachke Piping and Mechanicals rigging experience, capabilities, and training excels in the industrial rigging field. Our training record speaks for itself. The majority of our employees are EPRI Certified Riggers and all have OSHA Signal Person Qualifications. All of our rigging equipment is examined at each use and is certified annually by a third party.

Cutting Processes

Plasma Arc cutting requires an electrical current as well as an inert gas. To initiate the cut, the worker must create and electric arc between the electrode on the torch and the intended material. Once done, a trigger is pulled to allow the inert gas to flow and push through the heated source, resulting in a cut.

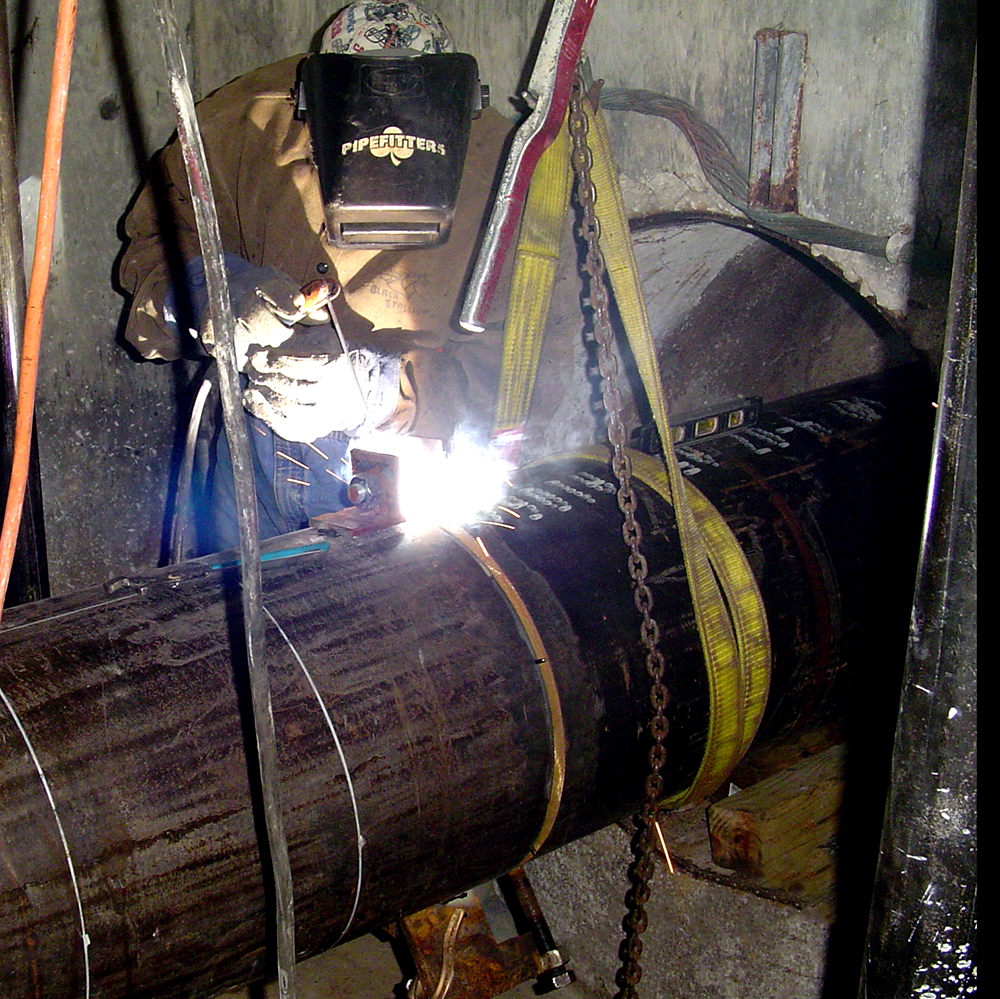

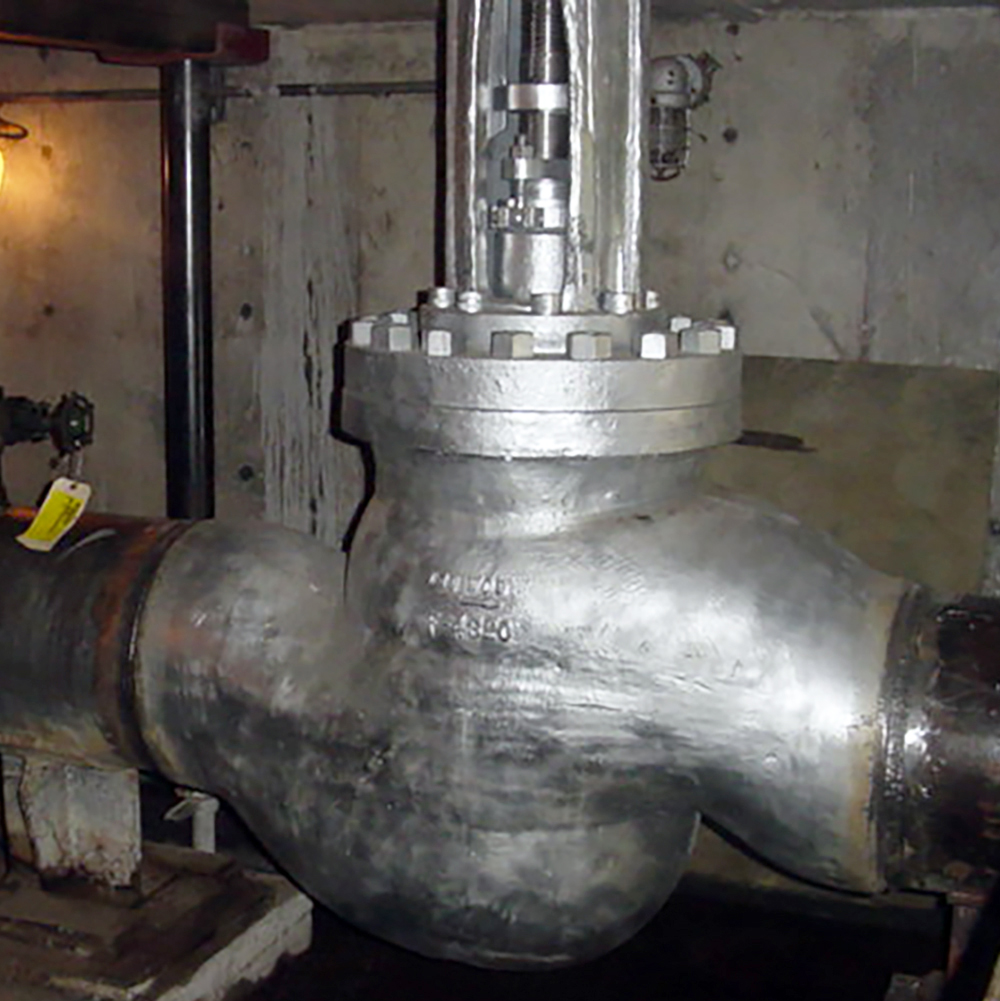

Welding Processes & Certifications

TIG (Tungsten Inert Gas) is used to weld steel, stainless steel, steel alloys, and titanium alloys. TIG uses a gas called Argon to shield the welding arc on the work surface to create a clean, high quality weld. Rachke Piping and Mechanical, Inc. Qualifies all their welders in accordance with ASME Section IX.

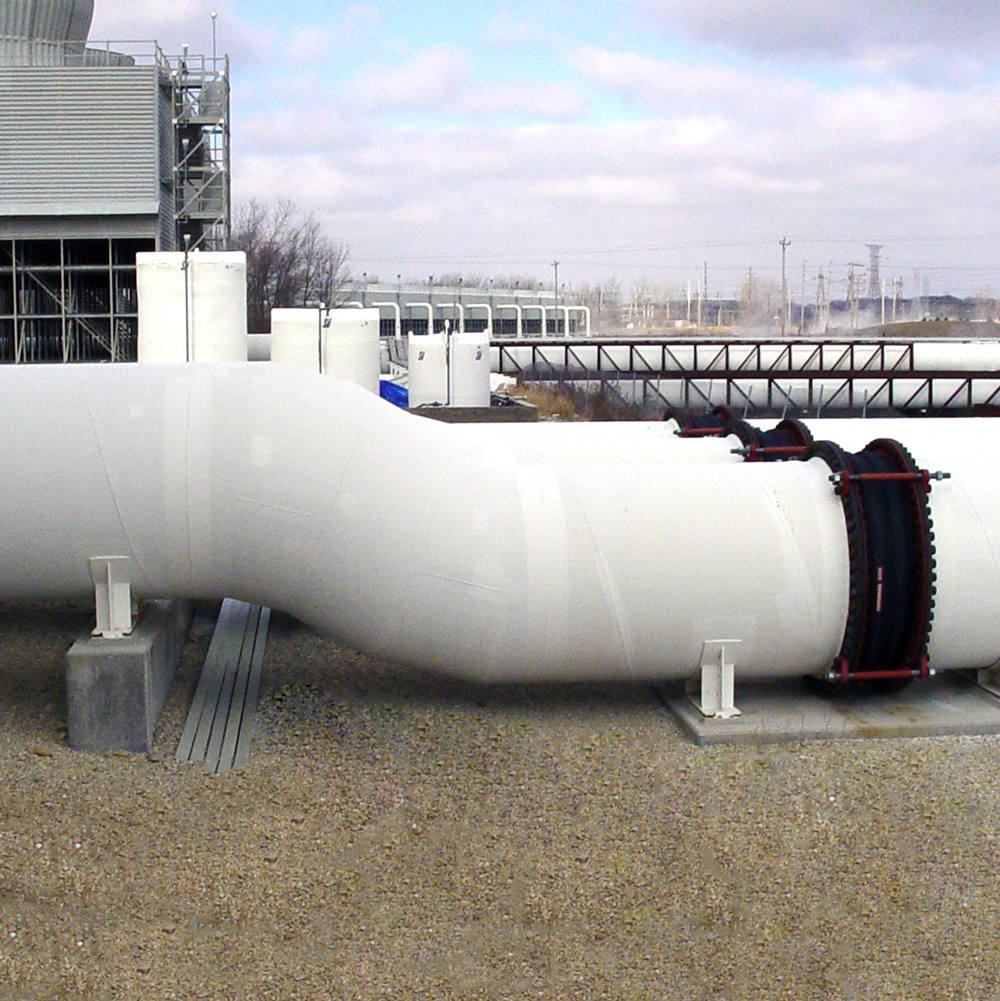

High-Density Polyethylene (HDPE) Plastic Fusion

Here at Rachke Piping we try to stay up to date on the latest materials and training techniques. We have noticed over the years that HDPE has become a very popular product used in our industry. Rachke Piping has been dedicated to training our personnel and staying up to date on the latest products, processes, and procedures.